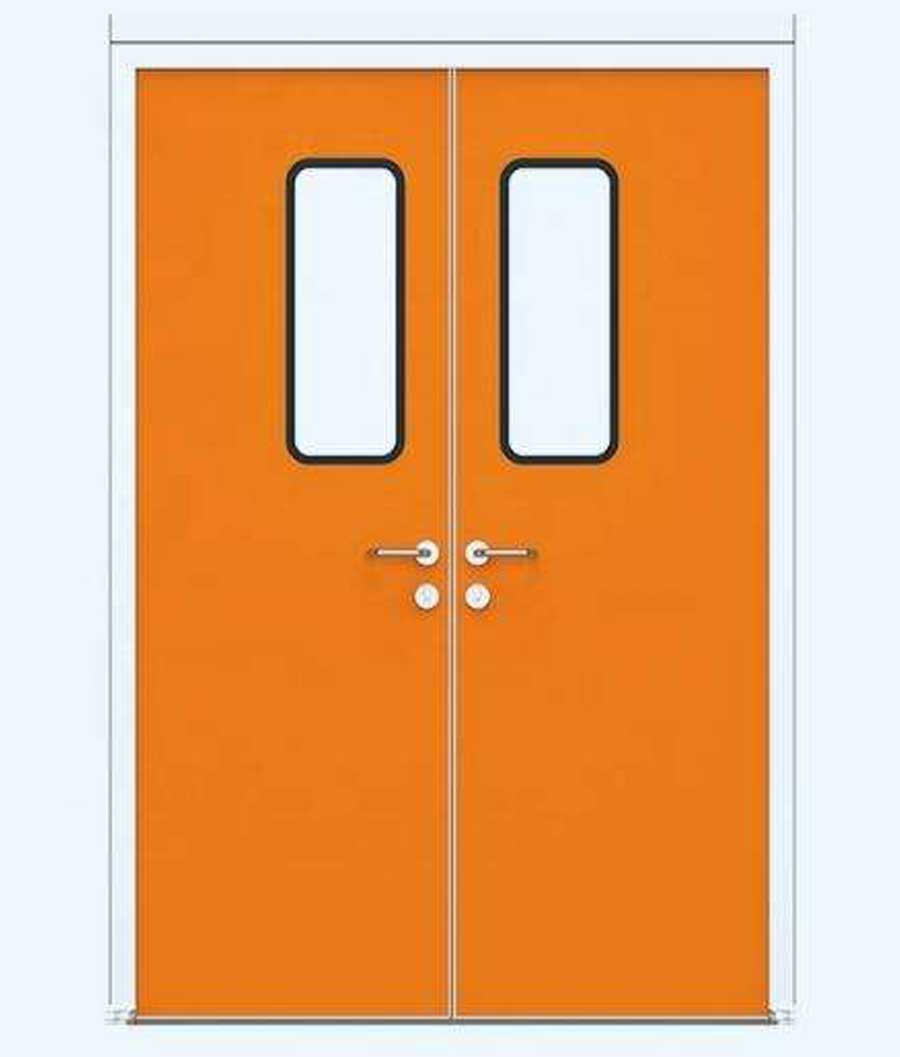

Sandwich Panel Door

Doors

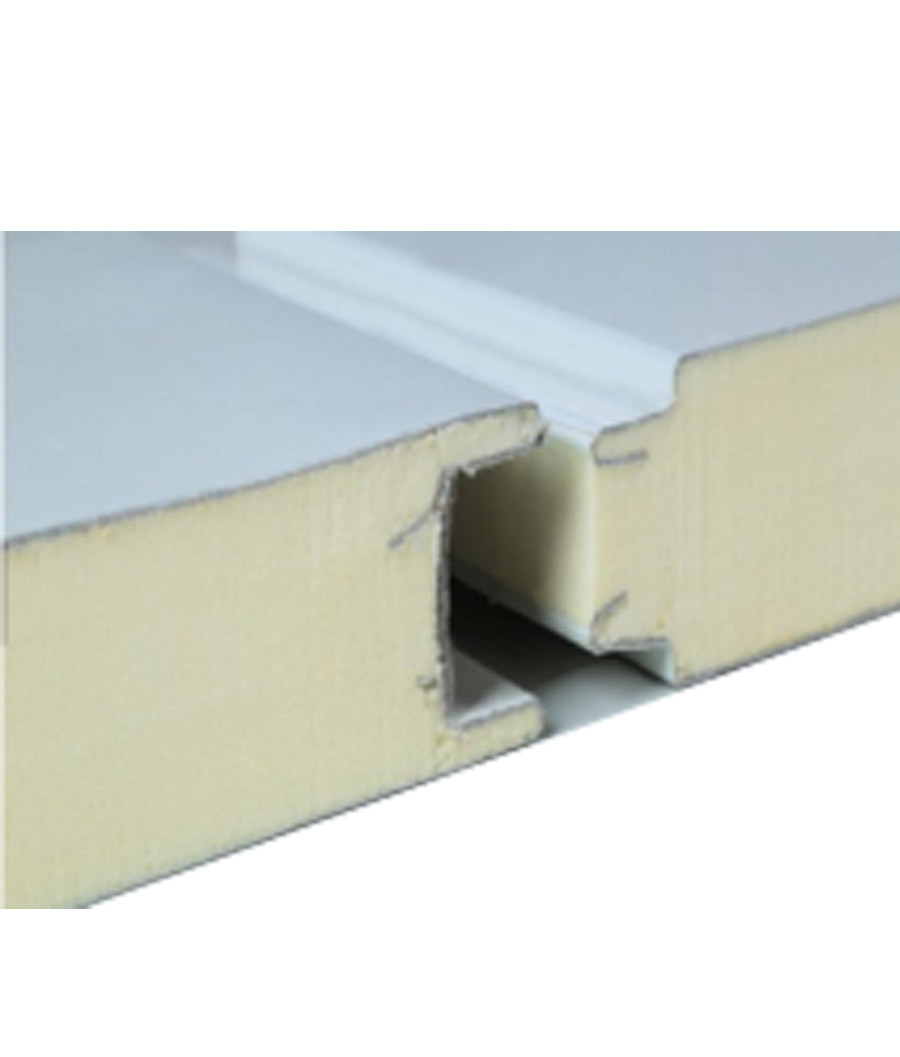

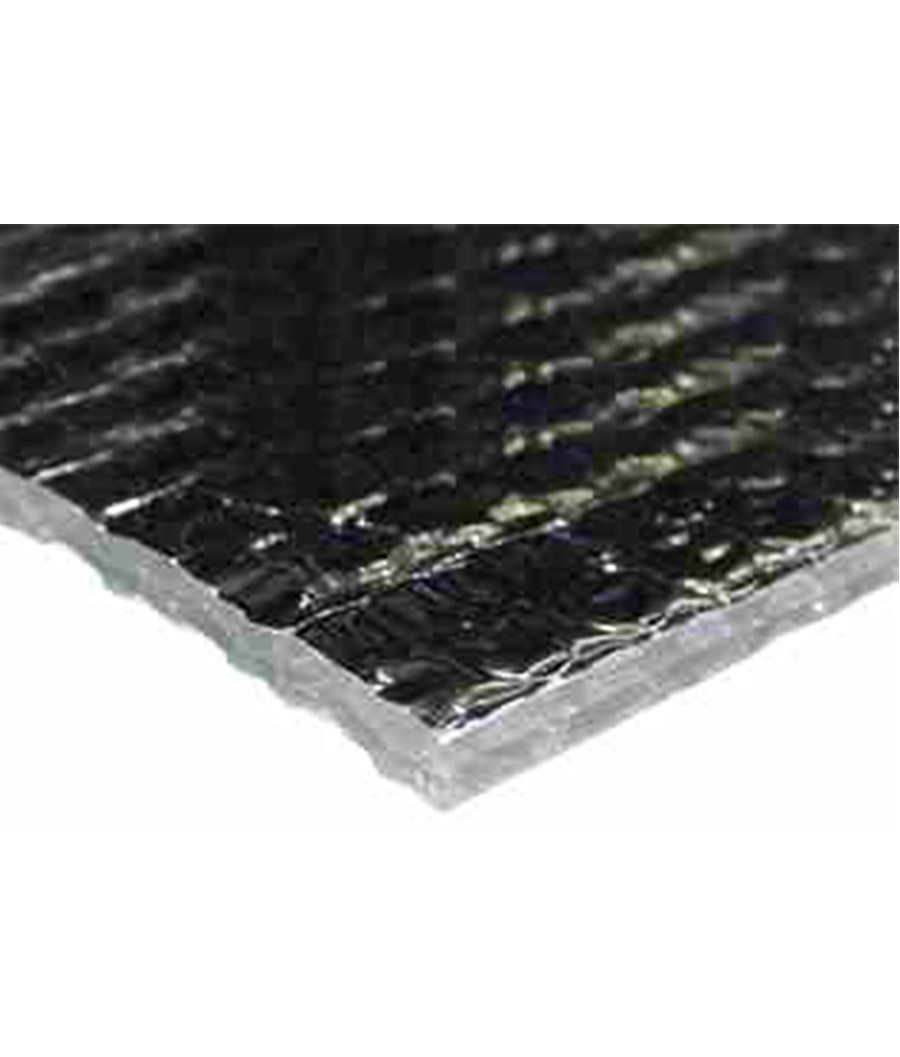

A sandwich panel door is a type of door made from insulated sandwich panels, which consist of two outer metal sheets with an insulating core material in between. These doors are popular in industrial, cold storage, and prefabricated buildings due to their thermal insulation, strength, and lightweight properties.

Advantages of Sandwich Panel Doors

- Excellent Thermal Insulation - PU/PIR cores provide high R-values, ideal for temperature control.

- Durability & Strength - Metal skins resist impacts, corrosion, and wear.

- Sound Insulation - Effective in noisy environments.

- Quick Installation - Lightweight and pre-fabricated for faster setup.

- Fire Resistance (with Rockwool) - Fire-rated cores provide safety in sensitive zones.

- Hygienic & Easy to Clean - Great for clean rooms and food industry use.

Please send your query of Sandwich Panel Door