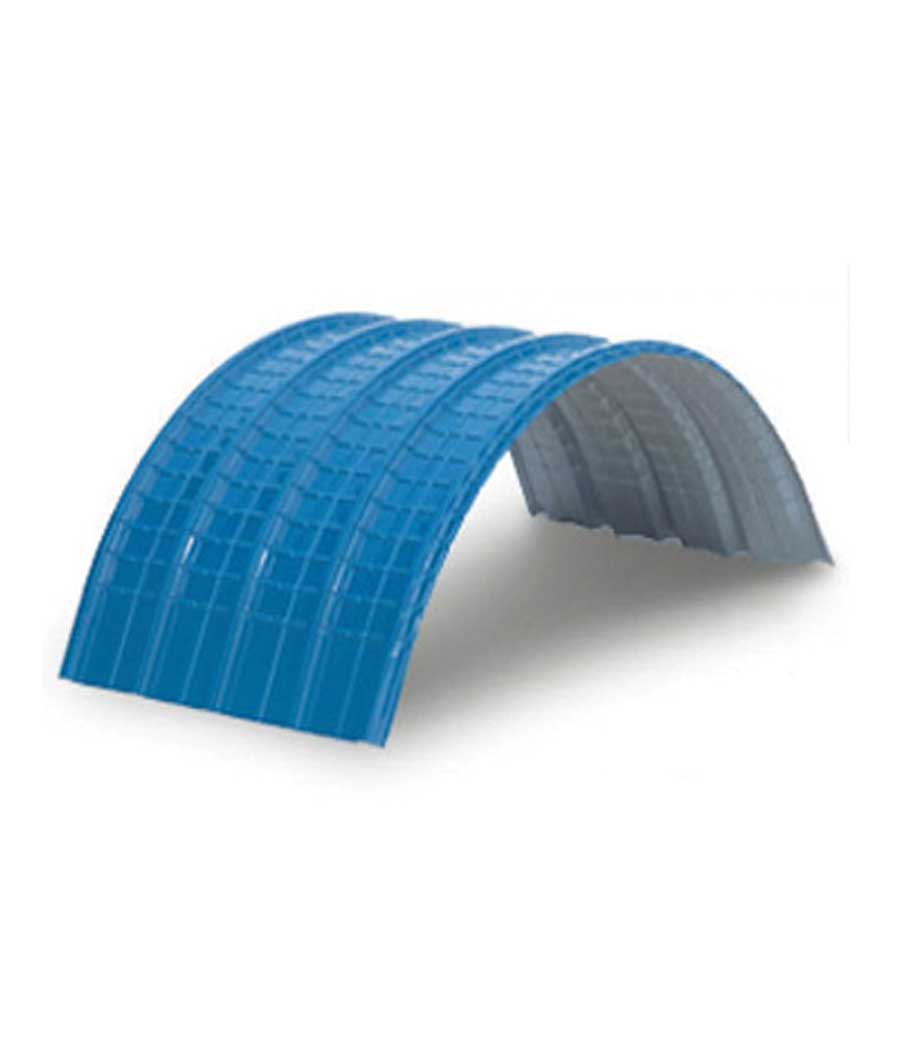

Curved Roofing Sheets

Profile, Corrugated Sheet

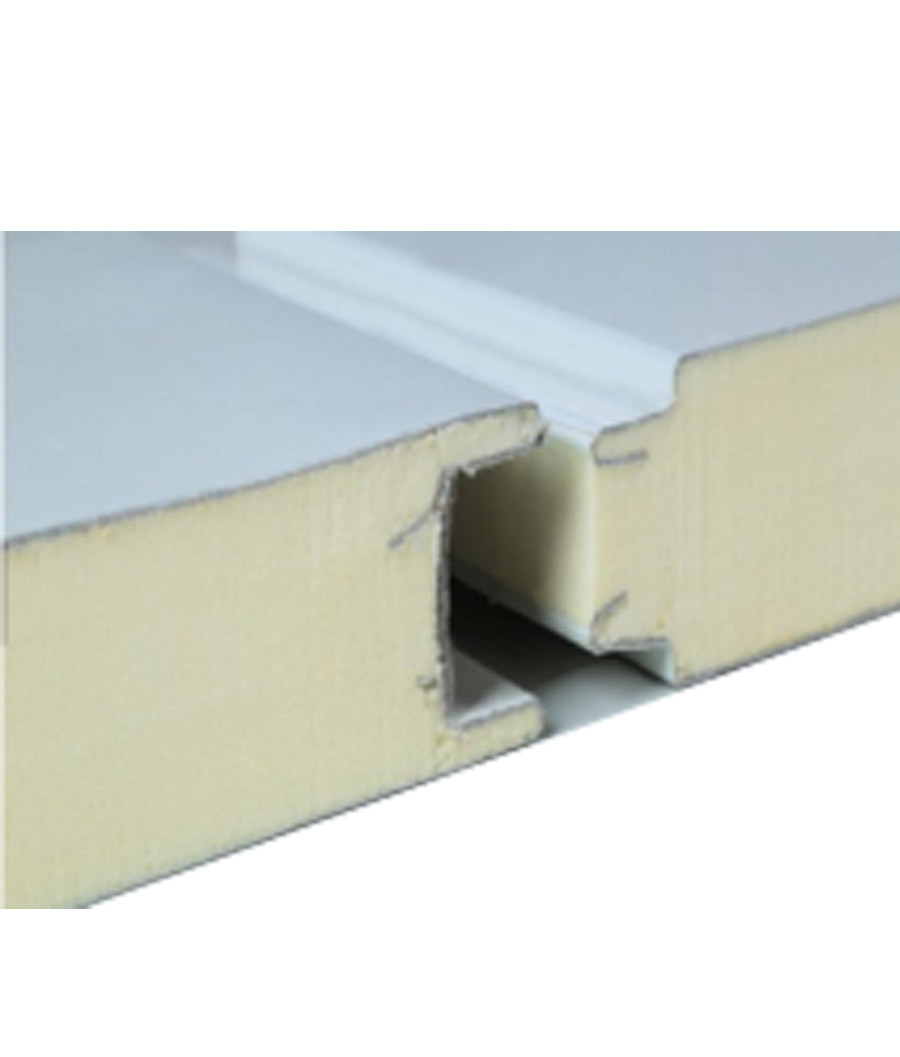

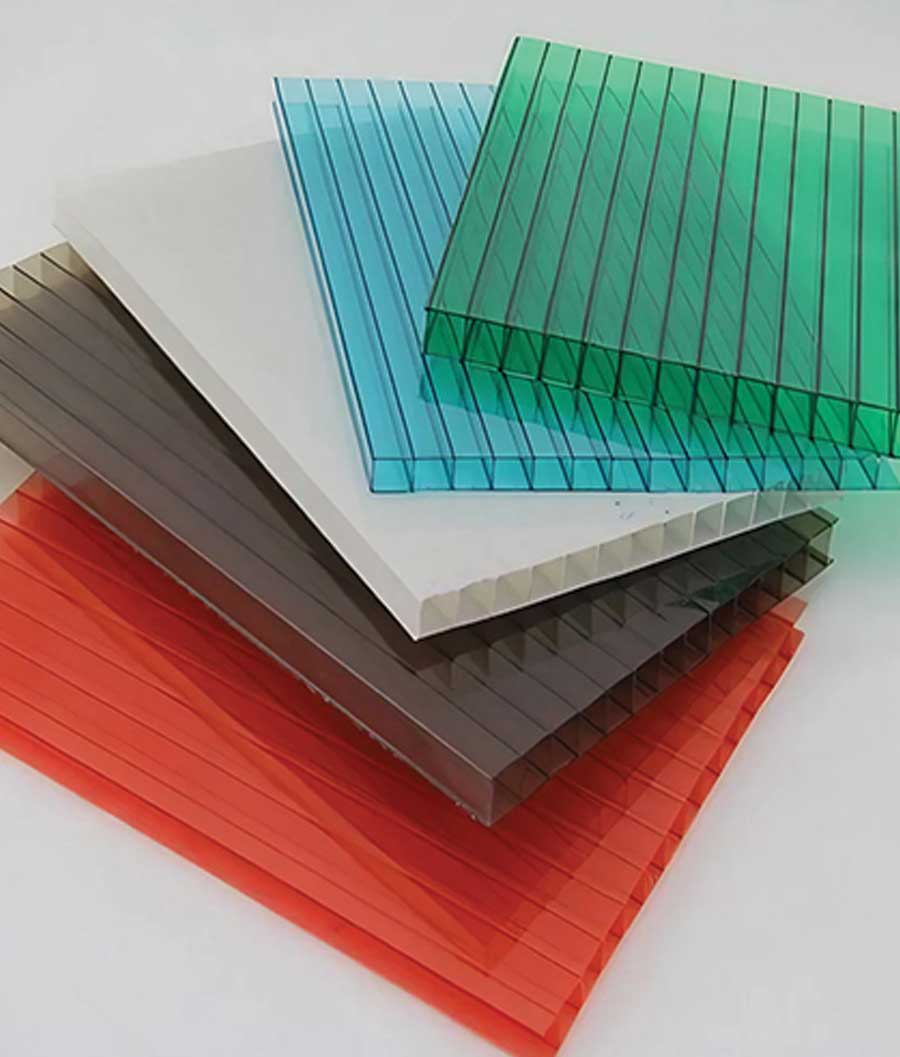

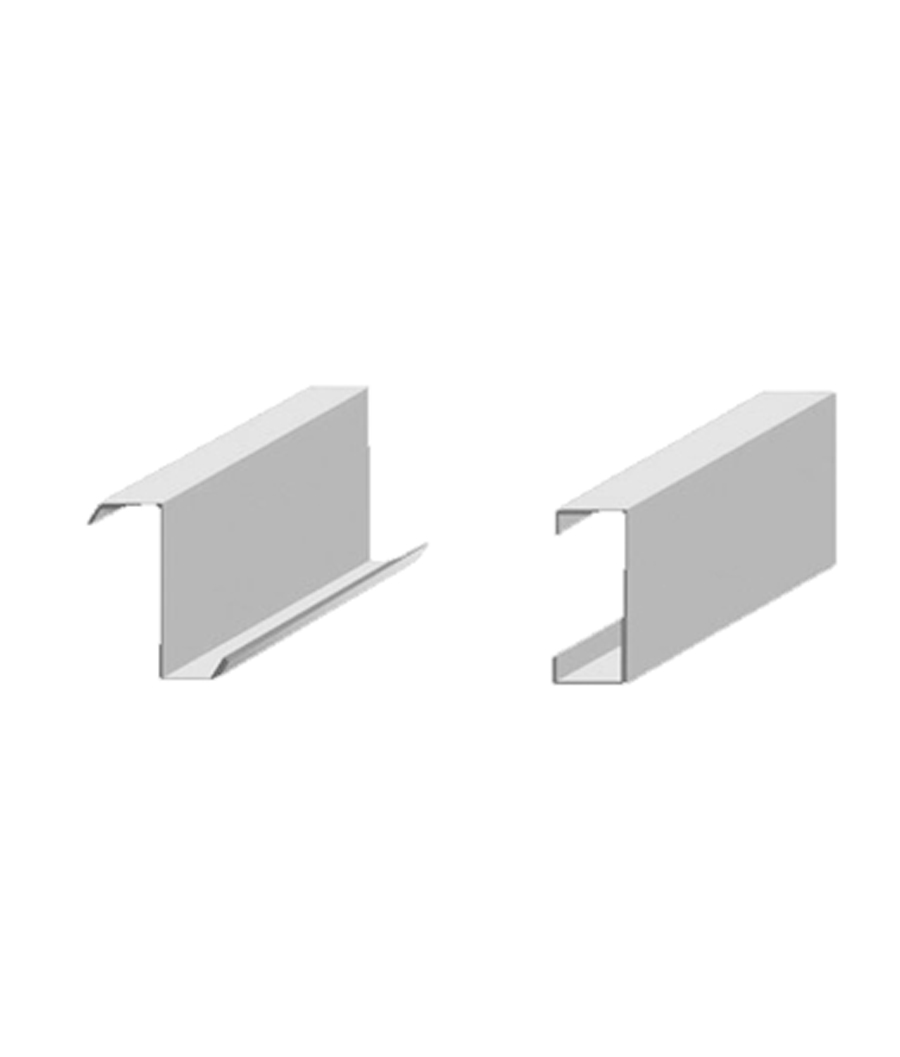

Curved roofing sheets are specialized roofing materials designed to create arched or curved roofs, which are both functional and aesthetically appealing. These sheets are commonly used in industrial, commercial, and architectural projects where a curved roof design is required. They provide excellent durability, weather resistance, and flexibility, making them suitable for a variety of applications. Below is a detailed overview of curved roofing sheets, including their types, materials, benefits, applications, and installation.

Benefits of Curved Roofing Sheets

- Aesthetic Appeal: Adds a unique and modern look to buildings.

- Durability: Resists weathering, corrosion, and UV radiation.

- Strength: Provides structural stability and load-bearing capacity.

- Weather Resistance: Excellent for drainage and snow shedding.

- Flexibility: Can be customized to fit various curved designs.

- Energy Efficiency: Reflects sunlight, reducing cooling costs.

- Low Maintenance: Requires minimal upkeep over its lifespan.

Please send your query of Curved Roofing Sheets