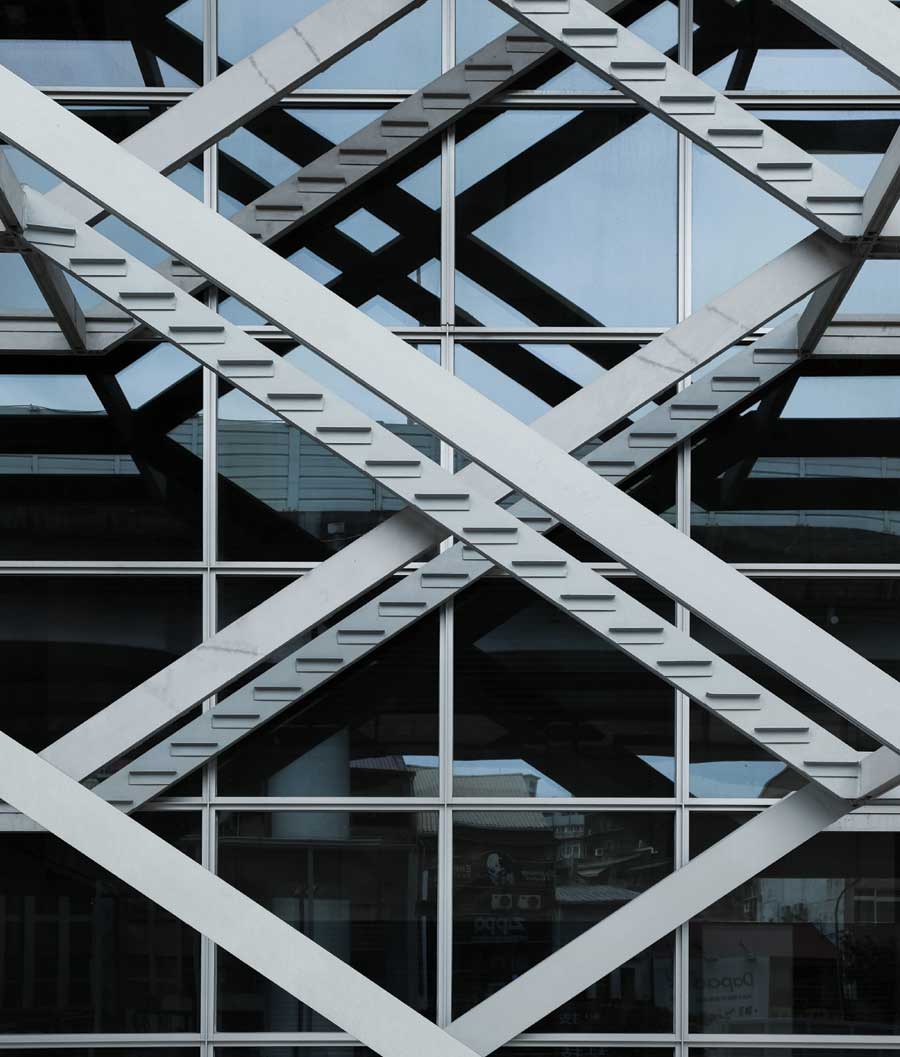

Bracing Systems

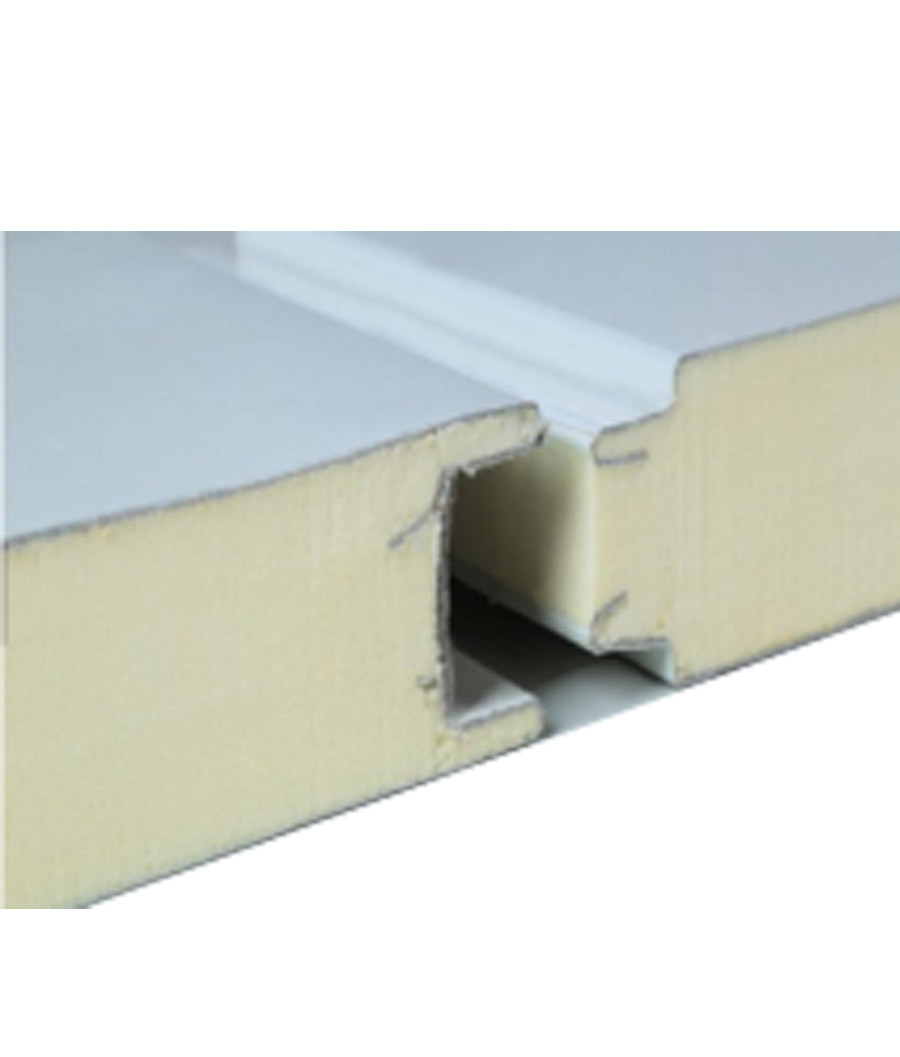

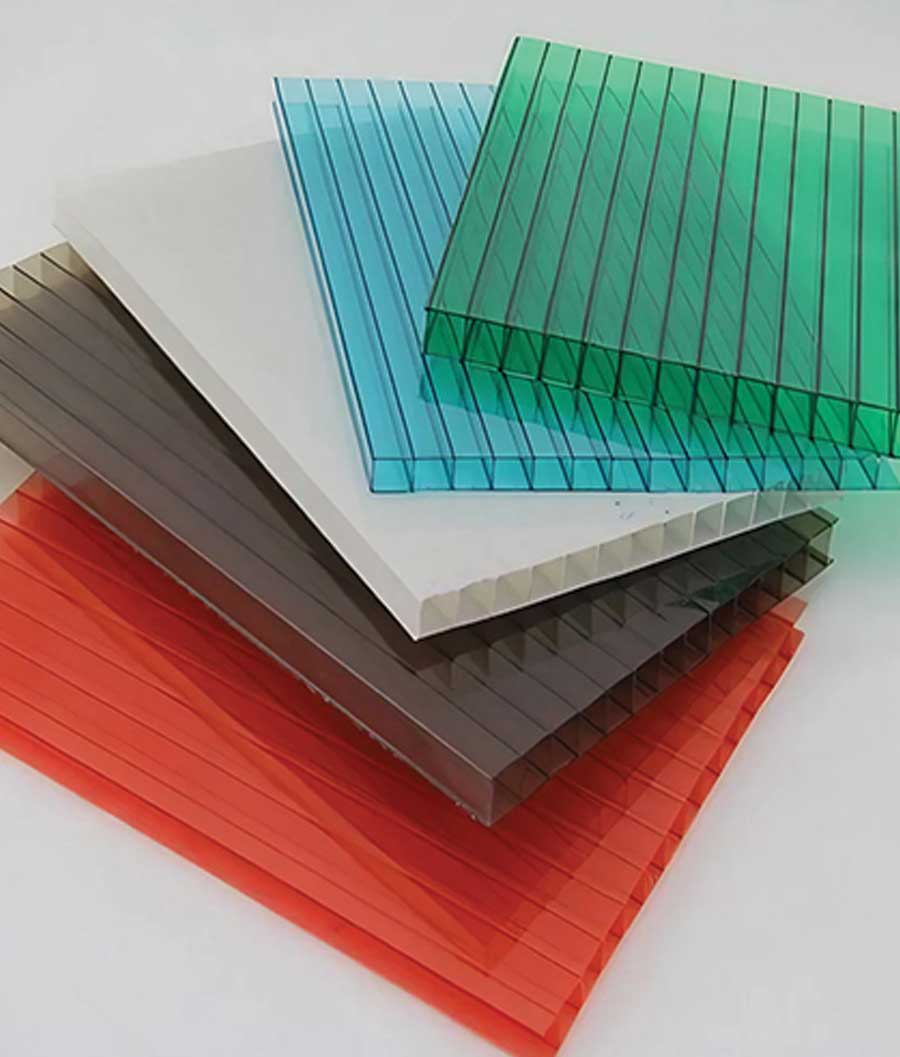

Building Secondary Products

Bracing systems are critical structural elements that provide stability, stiffness, and resistance to lateral forces (wind, seismic, crane loads) in steel buildings, bridges, and towers. They prevent buckling, sway, and collapse under dynamic loads.

Please send your query of Bracing Systems